Ahead of the Curve: The Gasoline Pumping Injector

At Stanadyne, we use advanced technology to face modern challenges every day. Whether it’s in business or technology, staying ahead of the curve is essential. It is our commitment to innovation that helps customers overcome their biggest tasks in an environment that is changing more rapidly than ever. Our most recent technology breakthrough is an example of this; and it starts with our solution to a modern engine challenge for two-wheeled vehicles in India.

Gasoline Pumping Injector

2018 is a pivotal year in the transportation industry. Many countries are migrating towards more stringent emissions norms and the demand for low-emission engines is growing faster than ever before. India is transitioning to BS VI emission regulations in 2019, and with this change, many of today’s two-wheel vehicles need an engine update to comply with the new standard. With more than 17 million two-wheel vehicles sold in India every year, manufacturers are moving quickly to stay in the market.

In order to meet BS VI emissions, an update of the fuel management system, shifting away from less efficient carburetor designs towards lower-emissions alternatives is required. One of these alternatives is port fuel injection. Of course, a shift of this magnitude comes at a price. Port fuel injection systems take up space, and on small vehicles such as motorbikes, installing such a system would be costly and time-consuming. With the impending change to BS VI, manufacturers are limited on time and are under pressure to find a better solution.

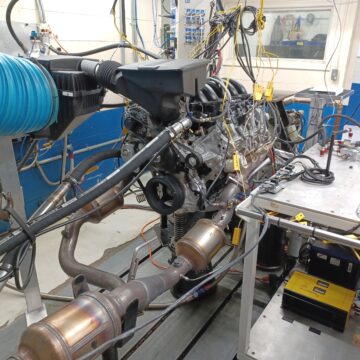

In response to this challenge, Stanadyne has developed an innovative solution to replace mechanical carburetors using a simple, fully electronic Gasoline Pumping Injector (GPI). In the GPI, the pump and injector are integrated into a single unit, making the system compact and cost-efficient. The GPI’s revolutionary design offers an alternative option to mitigate engine emissions, enabling manufacturers to meet the 2020 deadline more cost-effectively.

The Stanadyne Gasoline Pumping Injector provides precise injection timing and controllability, a critical factor in reducing emissions. Since the GPI is a pump and injector in a single unit, its design eliminates the need for an in-tank feed pump and allows for easy integration with existing engines. Stanadyne is working with several customers to get GPI systems on the road for 2020 and beyond.

At Stanadyne, we are constantly analyzing the problems faced by today’s engine manufacturers, applying years of industry experience to create customized solutions that address the most complex challenges facing fuel systems. This is how we stay ahead of the curve, developing solutions today for the engines of tomorrow.