Stanadyne Unveils New Hydrogen Fuel Injector at The Detroit Auto Show

Innovative multipurpose port injector also can deliver compressed natural gas, and dimethyl ether (DME) fuels DETROIT, September 14, 2022 – Stanadyne, a leading global fuel…

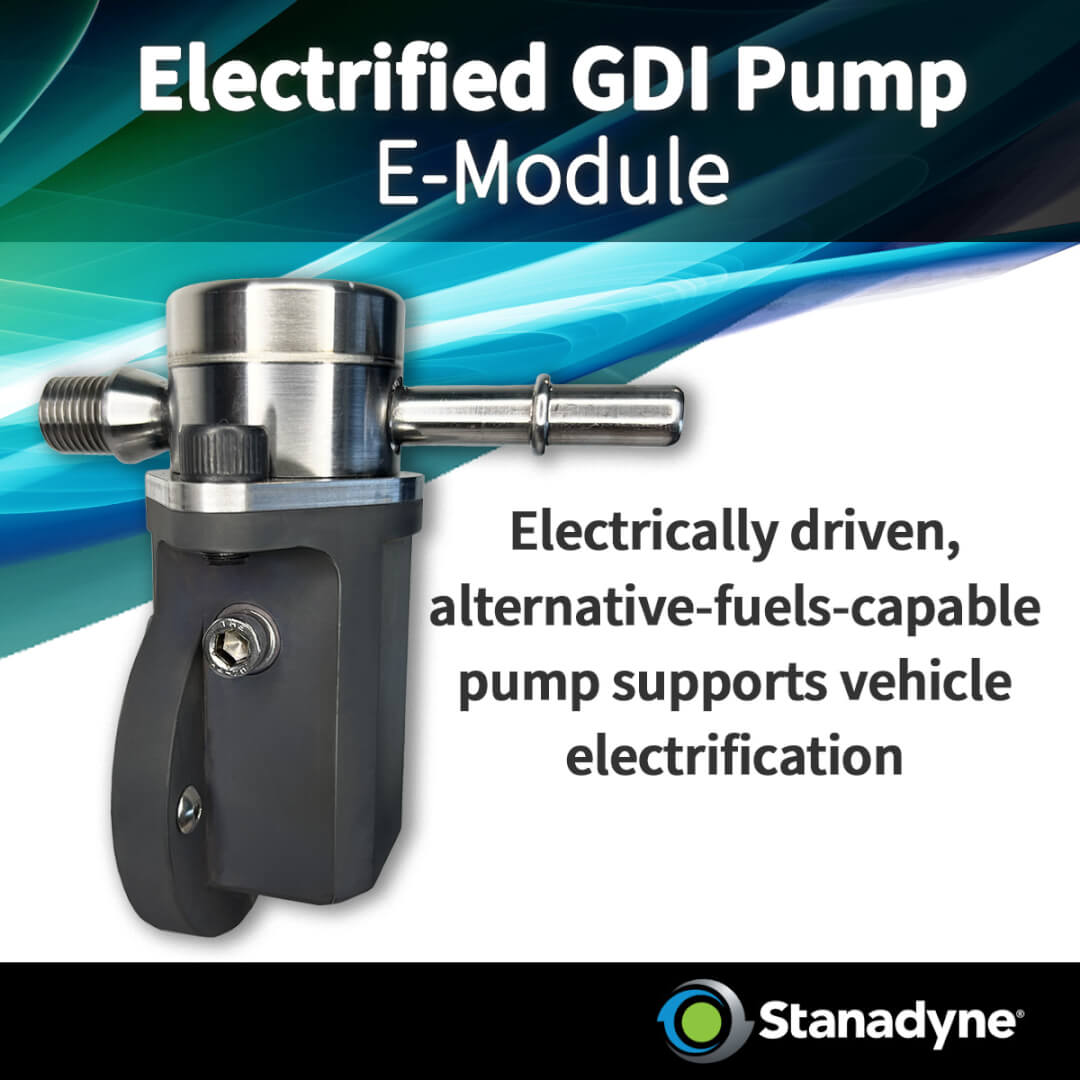

Stanadyne Electrified GDI Fuel Pump Module Makes Industry Debut

Electrically driven, alternative-fuels-capable pump supports vehicle electrification DETROIT, September 12, 2022 – Stanadyne, a leading global fuel and air management systems supplier, has developed an…

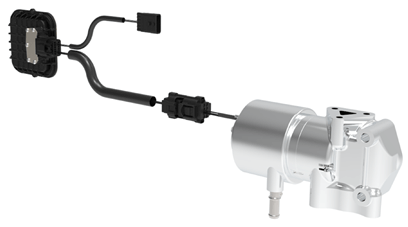

Stanadyne’s New Self-Cleaning EGR Valve Tackles The Tough Carbon Buildup Problem

Southfield, Michigan – May 11, 2022 – Stanadyne, a leading global fuel and air management systems supplier, has developed a modular, scalable exhaust gas recirculation…

Stanadyne India Wins The Machinist Super Shopfloor Award For Excellence In Innovation

Windsor, Connecticut – September 28, 2021 – The Stanadyne Near East Business Unit’s Chennai, India manufacturing and engineering services center has won the Excellence in…

Ahead of the Curve: The Gasoline Pumping Injector

Ahead of the Curve: The Gasoline Pumping Injector At Stanadyne, we use advanced technology to face modern challenges every day. Whether it’s in business or…

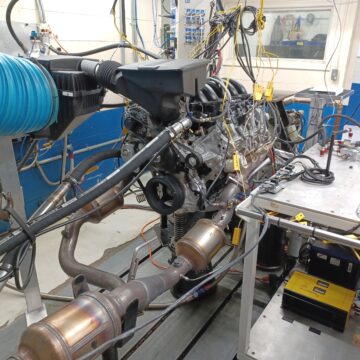

Stanadyne Unveils GDI Advances at SAE WCX18

Global Need for GDI Accelerates as Demand Grows for Greater Fuel Efficiency and Environmentally-Conscious Applications Detroit, Mich. (April 10, 2018) – The global market for…