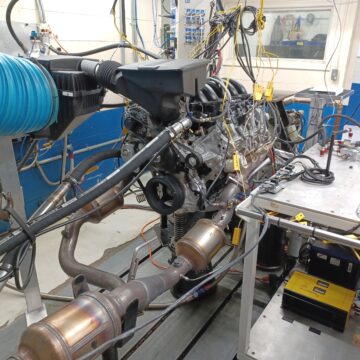

Ahead of the Curve: The Gasoline Pumping Injector

Ahead of the Curve: The Gasoline Pumping Injector At Stanadyne, we use advanced technology to face modern challenges every day. Whether it’s in business or…

Stanadyne Debuts New Fuel Systems at Auto Expo

New Fuel Systems Enable Cost-Effective Pathway to Achieve Upcoming Emissions Compliance for Small Engines in India NEW DELHI (Feb. 15, 2018) – Stanadyne, a global…