Research study shows new technology can enable widespread production and commercialization of lower-carbon lifecycle medium-duty LPG engines

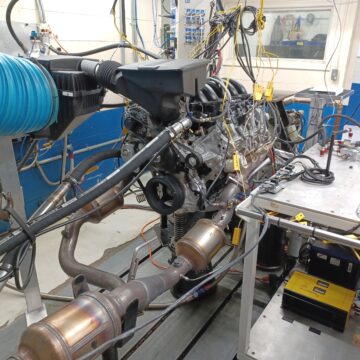

The test engine was updated with the Stanadyne components and operated on LPG direct injection.

Jacksonville, North Carolina – February 19, 2024 – Stanadyne, a leading global fuel and air management systems supplier, has participated in a ground-breaking research program that tested the feasibility of liquid propane gas (LPG) direct injection as a viable alternative fuel delivery option for medium-duty (class 3 to 7) engines. The research program was conducted by Katech Engineering and funded by the Propane Education & Research Council (PERC). The full research program performance report has been published on the PERC website’s Engines/Fuels Studies page.

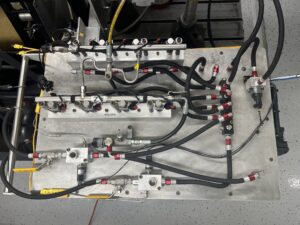

The direct injection injector flow and pump setup for liquid propane fuel engine testing.

The research program centers around the development and testing of a robust direct injection fuel system using new hardware and software inhibitor technologies to remove vapor lock barriers specific to propane. The test results showed these technologies enabled stable operation of the engine during hot-start, cold-start, hot-soak, and hot-idle conditions. The research also showed robust performance over a 250-hour durability test using a customized duty cycle.

“Overall, the proposed fuel system with in-house developed vapor lock inhibitor hardware and software addressed the design limitations faced by other LPG direct injection applications,” said Katech Engineering Lead R&D / Motorsport Engineer Eric Suits, who was the research program’s principal investigator. “The research results prove the efficacy of liquid propane as a fuel for direct injection, while addressing the previous design limitations.”

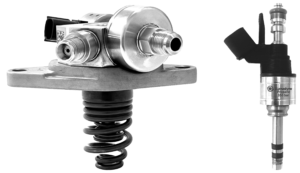

The research team worked directly with Stanadyne to design LPG-specific fuel pumps and injectors. The test engine was updated with the Stanadyne components and operated on LPG direct injection. The results of this propane configuration were able to meet all power and torque metrics of the baseline gasoline engine.

“Limited modifications were made to the test engine,” said Stanadyne Chief Engineer Srinu Gunturu. “Along with Stanadyne’s new LPG direct injection pump and injectors, the proposed technology shows a high level of feasibility for cost-effectiveness and widespread production and commercialization.”

Using LPG – particularly renewable propane produced as a byproduct of renewable diesel – has tremendous implications for cleaner propulsion, especially for the hard-to-electrify medium and heavy-duty vehicle market. LPG offers an approximate five to 10 percent reduction in carbon dioxide emissions and has almost no nitrogen oxide emissions compared to traditional diesel fuel. In addition, LPG does not require a particulate filter, has a lower total cost of ownership compared to other fuels on the market, and generates fewer carbon emissions with minimum engine adjustments. Renewable propane has a carbon intensity that is four times lower than that of conventional diesel.

“The partnership between Stanadyne, Katech, and PERC developed a first-of-its-kind propane direct injection system for medium and heavy-duty applications that will significantly improve engine efficiency and reduce emissions with low-carbon and renewable propane,” said PERC President and CEO Tucker Perkins. “We see this innovation as an enabling technology for a new generation of clean and efficient on-road, off-road, and power generation propane engines.”

The 98-page Katech and PERC Research Program Performance Report details all aspects of the two year assessment of liquid direct injected fuel systems for propane engines. The full report can be downloaded free of charge here. More information about Stanadyne’s innovative direct injection fuel pump and injector system used in research program can be found on the company’s website here.

About Stanadyne

Stanadyne designs, manufactures, remanufactures, and sells best-in-class vehicle and powertrain pumping, injection, air and fluid management, and control solutions. Founded in 1873, the company specializes in pioneering cleaner, more efficient fuel injection technology for engines that move our world and the aftermarket and remanufactured components that help keep them operating. Stanadyne provides customers with customized design, engineering, and manufacturing solutions from its United States, China, Italy, India, and United Arab Emirates locations in partnership with its global aftermarket service dealers and distributors network. For more information, visit Stanadyne.com.

About Katech

Katech Engineering is a premier performance engine and vehicle builder serving the corporate, aftermarket, and motorsport markets for more than 40 years. Our vision is to use what we’ve learned winning races at the most demanding venues worldwide – Indy, Le Mans, Daytona, Sebring, Dakar, and many more – to develop, build, and deliver the best engines and engineered products. For more information, visit katechengines.com

About PERC

The Propane Education & Research Council is a nonprofit that provides leading propane safety and training programs and invests in research and development of new propane-powered technologies. PERC is operated and funded by the propane industry. For more information, visit propane.com.

# # #

Media Contact:

Brad Warner

M: (248) 961-3071

Bwarner@sbcglobal.net