Jacksonville, North Carolina – September 13, 2023 – Stanadyne, a leading global fuel and air management systems supplier, has developed an innovative direct injection fuel pump and injector system to support a joint liquid propane gas (LPG) engine project with the Propane Education & Research Council (PERC) and Katech. The Stanadyne team overcame significant engineering challenges to develop the industry’s first medium-duty engine system that can deliver propane fuel at a constant 350-bar pressure directly into the engine while mitigating the potential for vapor lock. The innovation and partnership with PERC and Katech are part of Stanadyne’s drive to decarbonize the internal combustion engine.

Jacksonville, North Carolina – September 13, 2023 – Stanadyne, a leading global fuel and air management systems supplier, has developed an innovative direct injection fuel pump and injector system to support a joint liquid propane gas (LPG) engine project with the Propane Education & Research Council (PERC) and Katech. The Stanadyne team overcame significant engineering challenges to develop the industry’s first medium-duty engine system that can deliver propane fuel at a constant 350-bar pressure directly into the engine while mitigating the potential for vapor lock. The innovation and partnership with PERC and Katech are part of Stanadyne’s drive to decarbonize the internal combustion engine.

“Internal combustion engines are the workhorses of our economy, and this advancement in technology will help them run much more sustainably using renewable fuels,” said Stanadyne President David Zimmerman. “The opportunity to partner with PERC and Katech on this initiative aligns with our commitment to developing solutions bridging the significant adoption gap between fossil-fueled propulsion and low-carbon and zero-carbon fueled vehicles.”

“Internal combustion engines are the workhorses of our economy, and this advancement in technology will help them run much more sustainably using renewable fuels,” said Stanadyne President David Zimmerman. “The opportunity to partner with PERC and Katech on this initiative aligns with our commitment to developing solutions bridging the significant adoption gap between fossil-fueled propulsion and low-carbon and zero-carbon fueled vehicles.”

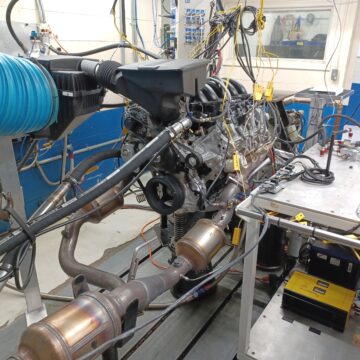

The robust Stanadyne fuel injector and pump design is delivered LPG by means of the vapor-lock inhibiting system consisting of both hardware and software strategies developed and designed by Katech. The combined system fueled a standard 6.6L GDI engine during a 250-hour performance and durability test, successfully demonstrating that Class 3-5 gasoline and diesel trucks can be effectively powered by LPG.

“The direct liquid injection system for high-vapor pressure gases such as LPG has been technically elusive until this joint partnership between PERC, Katech, and Stanadyne materialized,” said PERC Director, Research and Sustainability, Dr. Gokul Vishwanathan. “This technology will be a significant enabler for high efficiency and low emission propane and renewable propane powered engines and hybrids for the on-road and off-road markets.”

Beating Vapor Lock

The Stanadyne-Katech joint development team were able to overcome the challenge of “vapor lock” – a common technical challenge affecting direct injection for liquified gasses, including LPG. Liquified gasses tend to vaporize, which can interrupt fuel pump operation and put commercially viable LPG direct fuel injection out of reach.

“The engineering hurdles we faced with this project were numerous, particularly the challenge of vapor lock,” said Stanadyne Manufacturing Engineering Senior Manager Srinu Gunturu. “Ultimately, we were able to overcome them and, in the process, improve both engine performance and efficiency. We are excited to help tap the incredible potential of cleaner alternative fuels.”

Stanadyne helped beat this long-standing challenge with a modified pump design with a unique liquid flow path through the pump. Stanadyne engineers also modified the fuel injectors with additional coatings for greater wear resistance. Together with Katech’s vapor-lock inhibiting system, the Stanadyne components successfully allowed vapor to return to the fuel tank while continuously delivering liquid fuel to the pump for lubrication and cooling.

“The ability to partner with PERC and Stanadyne has yielded a promising step forward in LPG DI technology”, said Katech Lead Engineer Eric Suits, “Stanadyne’s background in DI fuel systems has allowed Katech to focus more directly on the development and advancement of vapor lock systems, LPG DI engine controls, and future LPG DI applications. This has produced a truly complimenting control strategy and delivery system necessary to ensure reliable LPG DI operation under all operating conditions. All of this would not have been possible without PERC and their collaboration of LPG-DI benchmarking and vapor-lock inhibiting development with Katech.”

Stanadyne applied its fuel injector expertise to create an optimal spray pattern that addresses the unique properties of liquid propane under high pressure. The company developed unique spray hole characteristics and targeting to tightly deliver propane. This helps ensure optimal air-fuel mixing for very efficient combustion that generates the same power output as gasoline. In addition, using direct injection avoids the 20 percent power reduction associated with port fuel injection due to gaseous propane replacing air volume in the intake stroke.

“Direct injection of propane at high pressure has a unique challenge in spray preparation” said Stanadyne Global Chief Engineer Mike Hornby. “The injector needs to ensure good penetration and mixing in the combustion chamber.”

Low-Carbon Implications

Using LPG – particularly LPG produced renewably as a byproduct of renewable diesel – has tremendous implications for cleaner propulsion, especially for the hard-to-electrify medium and heavy-duty vehicle market. LPG offers an approximate five to 10 percent reduction in carbon dioxide emissions and has almost no nitrogen oxide emissions compared to traditional diesel fuel. In addition, LPG does not require a particulate filter, has a lower total cost of ownership compared to other fuels on the market, and generates fewer carbon emissions with minimum engine adjustments. Renewable LPG has a carbon intensity that is four times lower than that of conventional diesel.

The successful test of the LPG engine provides Class 3-5 trucks a potential decarbonization solution that could help the industry meet the rigorous demands of ultra-low emissions mandates going into effect in 2027. Longer term, this breakthrough LPG direct fuel injection pump and injector solution will facilitate cleaner propulsion and allow operators to keep their internal combustion engine commercial vehicles working hard for them while still meeting sustainability goals.

About Stanadyne

Stanadyne designs, manufactures, remanufactures, and sells best-in-class vehicle and powertrain pumping, injection, air and fluid management, and control solutions. Founded in 1873, the company specializes in pioneering cleaner, more efficient fuel injection technology for engines that move our world and the aftermarket and remanufactured components that help keep them operating. Stanadyne provides customers with customized design, engineering, and manufacturing solutions from its United States, China, Italy, India, and United Arab Emirates locations in partnership with its global aftermarket service dealers and distributors network. For more information, visit Stanadyne.com.

About Katech

Katech Engineering is a premier performance engine and vehicle builder serving the corporate, aftermarket, and motorsport markets for more than 40 years. Our vision is to use what we’ve learned winning races at the most demanding venues worldwide – Indy, Le Mans, Daytona, Sebring, Dakar, and many more – to develop, build, and deliver the best engines and engineered products. For more information, visit katechengines.com

About PERC

The Propane Education & Research Council is a nonprofit that provides leading propane safety and training programs and invests in research and development of new propane-powered technologies. PERC is operated and funded by the propane industry. For more information, visit Propane.com.

# # #

Media Contact:

Brad Warner

M: (248) 961-3071

bwarner@s5c.72e.mywebsitetransfer.com