New Fuel Systems Enable Cost-Effective Pathway to Achieve Upcoming Emissions Compliance for Small Engines in India

NEW DELHI (Feb. 15, 2018) – Stanadyne, a global fuel injection systems developer headquartered in Windsor, Connecticut, debuted two new fuel systems at the Feb. 8-11 Auto Expo components show in New Delhi that offer a differentiated approach to meet India’s forthcoming small engine emissions regulations.

Stanadyne’s Gasoline Pumping Injector (GPI) and Solenoid Controlled Unit Pump (SCUP) have been developed as cost-effective replacements for mechanical systems in two- and three-wheeler applications and enable manufacturers to achieve India’s emissions norms.

The GPI is an integrated pump and injector designed to replace mechanical carburetors commonly used on small gasoline engines today. The SCUP is an electronically controlled unit pump that offers precise timing and fuel delivery control and is an alternative to diesel common rail technology.

“This (GPI and SCUP) technology fits in the footprint of today’s mechanical systems; offering a direct advantage over other options in the market that require manufacturers to make major design changes to their engines,” said Jayabalan S, Stanadyne Senior General Manager of Application Engineering. “With manufacturers working to meet 2019/2020 emissions requirements of small diesel and gasoline engines, we’re supplying low-cost solutions that require fewer engine modifications compared to more complex systems like port fuel injection and diesel common rail.”

Stanadyne’s Sanjay Chadda, Managing Director (left) and Dr. John Pinson, President & CTO (right) revealed two new products – the Gasoline Pumping Injector (GPI) and Solenoid Controlled Unit Pump (SCUP) at the 2018 Auto Expo Components Show in New Delhi February 8th – 11th. Designed to meet BS-VI norms through electronic fuel injection systems, the products offer cost-effective alternatives to traditional mechanical systems.

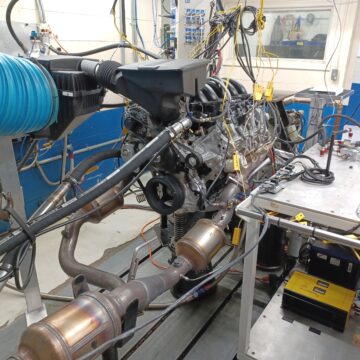

Also showcased at the Auto Expo were Stanadyne’s other diesel and gasoline fuel systems – Gasoline Direct Injection (GDI) pumps and Diesel Common Rail (DCR) systems – which marked their inaugural exhibition in India, though Stanadyne has been manufacturing products in the country for nearly 10 years.

Stanadyne, which developed the world’s first 200 bar GDI pump for the automotive market in 2006, today designs GDI technology primarily for 3-cylinder and above passenger-vehicle engines.

The company’s DCR technology is developed for the harshest operating conditions and low-lubricity fuels. The high-pressure pumps are available in two or four plunger configurations and sized for engines up to 16L.

“With manufacturing facilities strategically placed across the globe, Stanadyne is committed to enabling the next generation of clean and fuel-efficient engines,” said Stanadyne President, Chief Technology Officer Dr. John Pinson. “Solving the unique regional challenges faced by our customers with tailor-made products is part of our company philosophy. The technology in our GPI and SCUP products exemplifies this business blueprint.”