Fuel Systems Specialist Combines Flexible Design and High-Technology for Automakers Next-Gen Engines Beginning in 2018

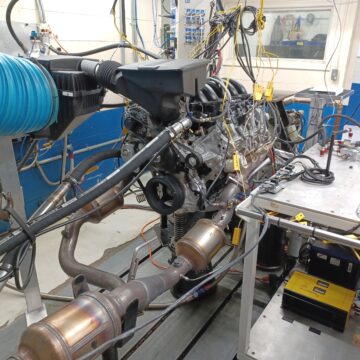

Stanadyne recently won a contract to supply nearly 4 million gasoline direct injection fuel pumps for a high-volume next-gen Engine program to be used in applications including pickup trucks and performance vehicles

Stanadyne, a fuel injection system developer based in Windsor, Connecticut, today announced it has won a contract to supply 3.8 million gasoline direct injection (GDI) pumps to a domestic automotive manufacturer. The four-year contract follows the recent announcement that Stanadyne had just manufactured its 2 millionth GDI pump.

“Stanadyne products serve a diverse range of gasoline engines,” says Stanadyne CEO David Galuska. “We design specialized fuel systems and adapt to manufacturer’s needs. Our flexible approach allows automakers the advantage of designing engines with fewer restrictions.”

The new contract, which runs from 2018 – 2024, is an extension of the current agreement with the same manufacturer, making the total engagement 11 years. The GDI pumps being supplied feature Stanadyne’s latest high-performance, fuel saving designs and include additional features specifically developed to meet the needs of their next-gen engines for performance vehicles and pickup trucks.

“This new GDI pump will set important technical and market benchmarks in packaging, weight and noise abatement,” says Stanadyne President and CTO Dr. John Pinson. “Our groundbreaking design incorporates advanced material coatings and our proprietary QuietTechTM technology to achieve high performance in a quiet and lightweight package.”

Stanadyne will expand its manufacturing capacity in Jacksonville, North Carolina to accommodate the new program beginning in March 2016. The 130,000 sq. ft. facility currently serves as the company’s main production facility for GDI pumps and employs 280 people. The start of production for the new pump is slated for 2018 with the first delivery occurring in April of that year.