Meet the Expert: Srinu Gunturu – Stanadyne’s High-Pressure Pro

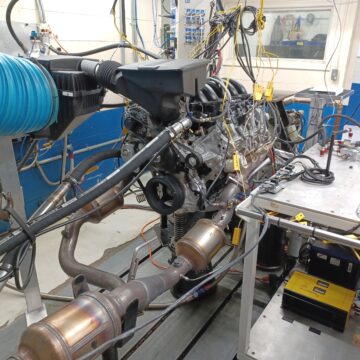

Stanadyne’s High-Pressure Pro Stanadyne’s Senior Manager of Engineering for Gas Products, Srinu Gunturu has been raising the bar for high-pressure gasoline direct injection fuel systems…

Meet Michael Hornby – Stanadyne’s Fuel Injection Expert and Innovator

Fuel Injection Expert and Innovator Stanadyne continues to assemble top talent charged with developing internal combustion engine (ICE) solutions offering customers greater efficiency and lower…