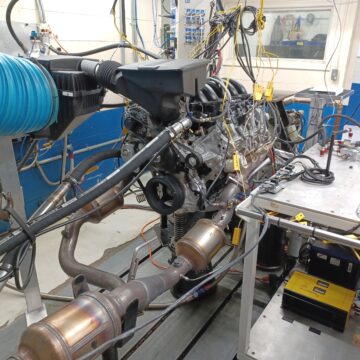

Stanadyne Unveils GDI Advances at SAE WCX18

Global Need for GDI Accelerates as Demand Grows for Greater Fuel Efficiency and Environmentally-Conscious Applications Detroit, Mich. (April 10, 2018) – The global market for…

Minimizing Fuel System Noise

Being Quiet is the Best Way to Be Heard: Minimizing Fuel System Noise Drivers expect a lot out of their vehicles, and one of these…