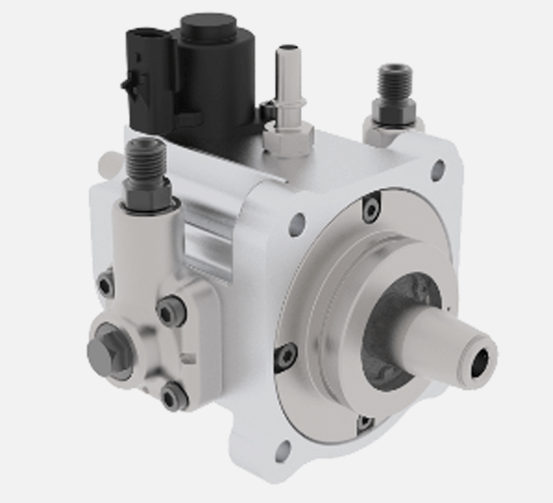

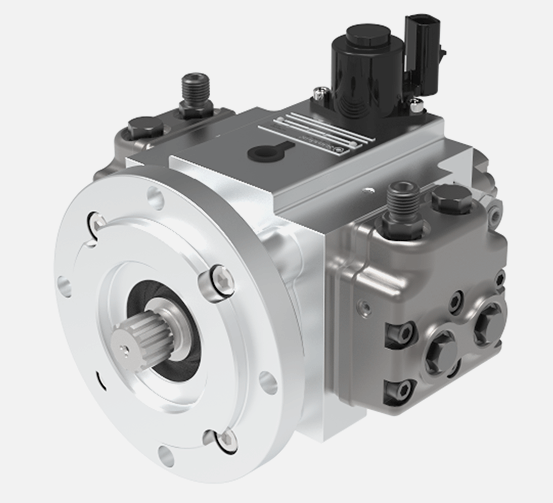

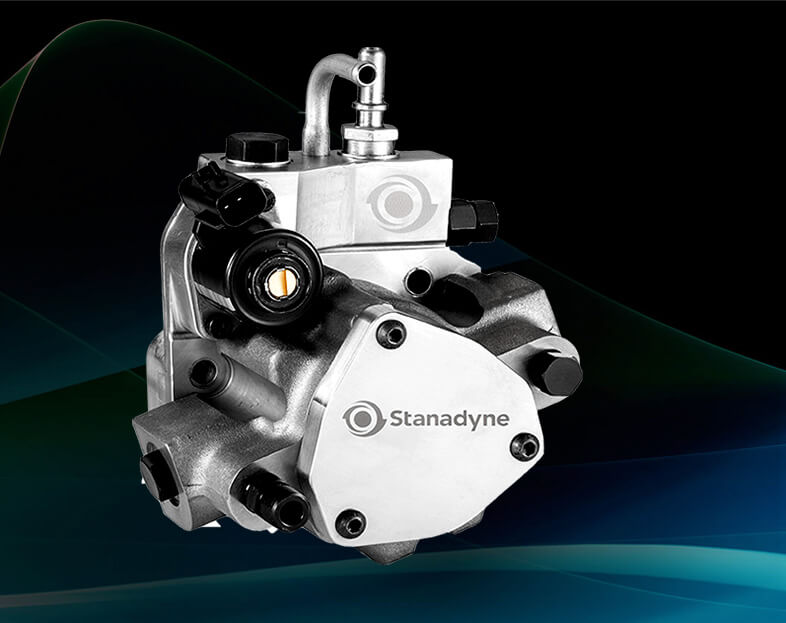

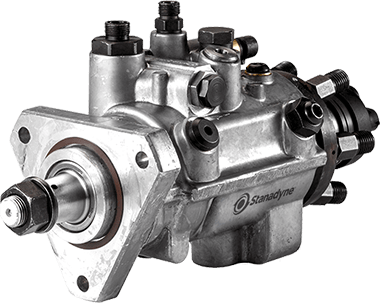

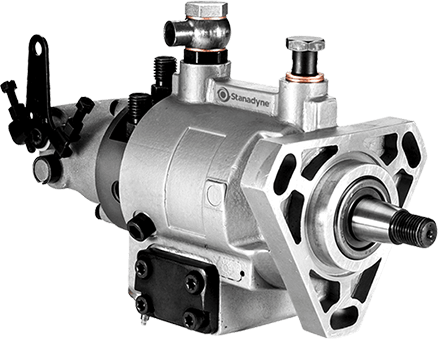

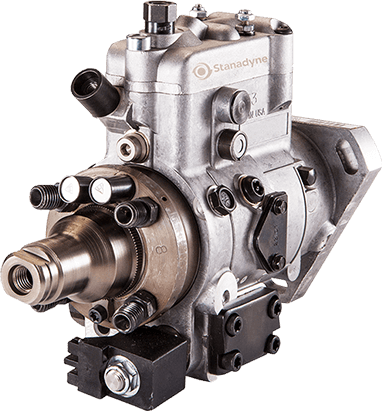

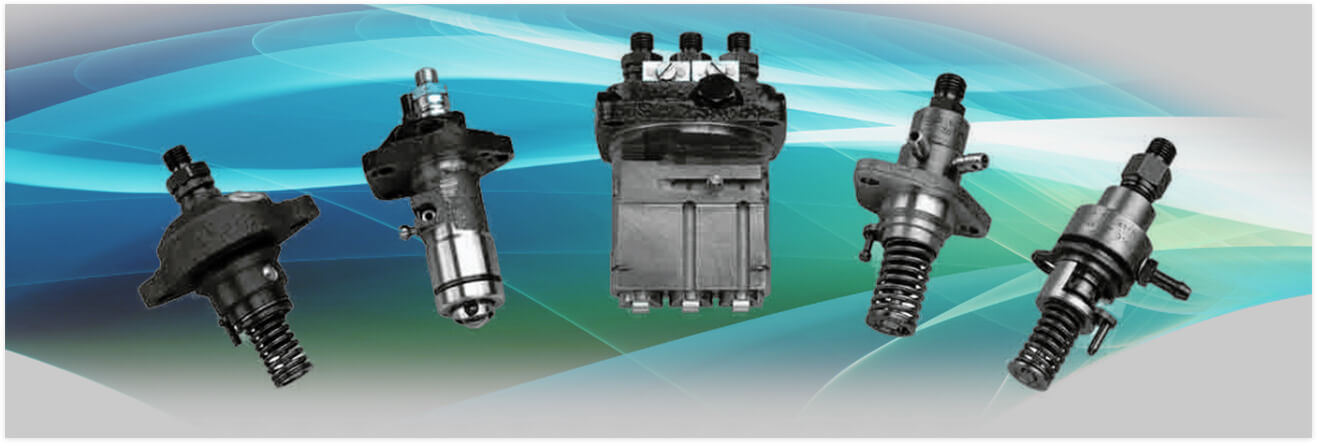

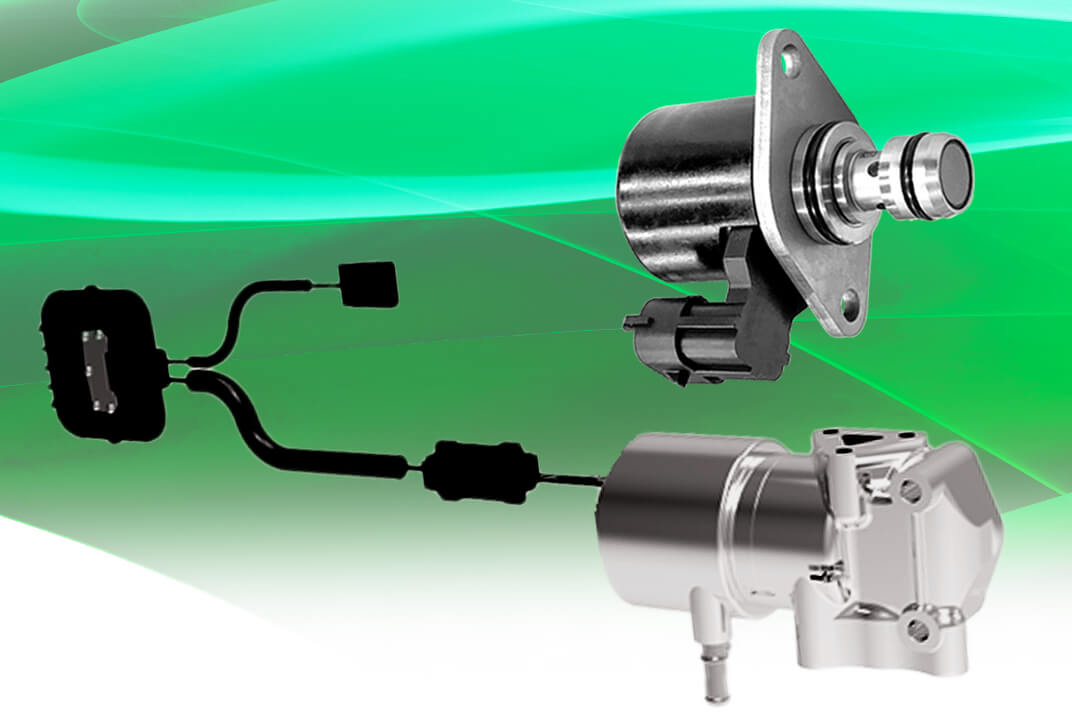

Stanadyne designs, manufactures, and remanufactures leading internal combustion engine fuel delivery solutions for diesel and alternative fuel wet systems and components in support of customer green initiatives. Our high-quality aftermarket, service, replacement, and performance products keep diesel engines running cleanly now and in the future.

Driving Decarbonization

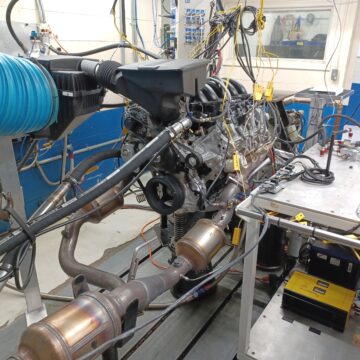

Stanadyne is investing in research and development to support decarbonization of the diesel engine. Our innovations help bridge the significant adoption gap between fossil-fueled propulsion and low-carbon or zero-carbon fueled vehicles.

Sustainable Propulsion

Stanadyne is committed to nurturing sustainable propulsion. Our company embraces responsible propulsion solutions to meet our customers’ diverse mobility needs.

Low-Carbon & Zero-Carbon Fuels Compatibility

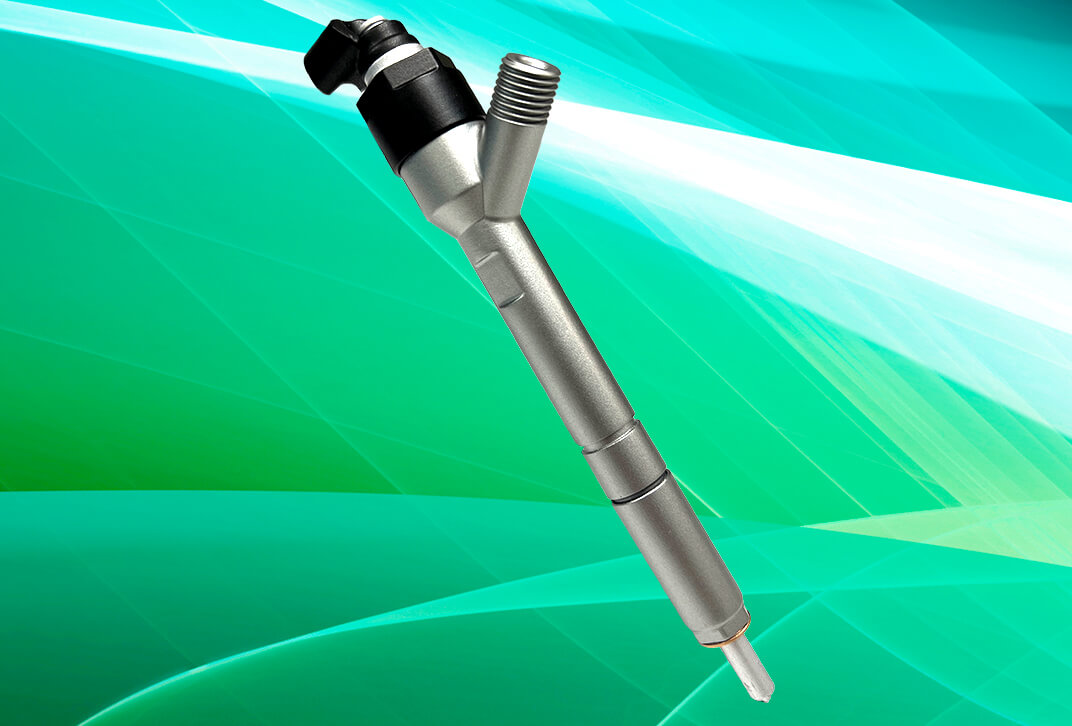

Stanadyne’s fuel delivery systems lower emissions, increase efficiency, and improve performance on the path to zero-carbon fuel compatibility.

Up to 3,000 Bar injection pressure

Up to 3,000 Bar injection pressure