Stanadyne Appoints Jeff Blake PurePower Technologies Managing Director

Blythewood, South Carolina – November 15, 2022 – Stanadyne, a leading global fuel and air management systems supplier, has appointed Jeff Blake as Managing Director…

Stanadyne India Honored with a 2022 Atmanirbhar Bharat Award

Chennai, India – October 20, 2022 –Stanadyne’s Solenoid Controlled Unit Pump (SCUP) innovation won a 2022 Atmanirbhar Bharat Award in recognition of outstanding professional achievement and…

Stanadyne’s New Corrosion-Resistant Inlet Metering Valve Designed to Extend DCR Fuel Pump Life

Southfield, Michigan – August 12, 2022 – Stanadyne, a leading global fuel and air management systems supplier, has developed a new Inlet Metering Valve (IMV)…

Stanadyne India Presented with a 2022 Times Business Award

Chennai, India – July 7, 2022 –Stanadyne India received a 2022 Times Business Award in the Fuel Pump Manufacturing category from Optimal Media Solutions, a…

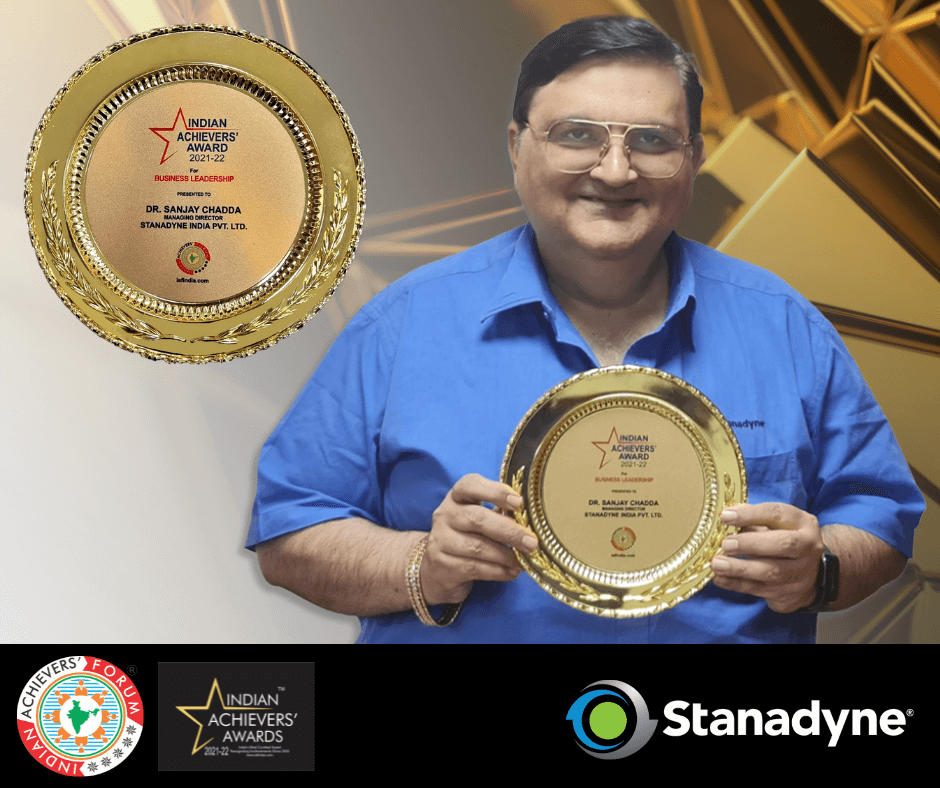

Stanadyne’s Dr. Sanjay Chadda Receives 2021-2022 Indian Achievers’ Award for Business Leadership

Chennai, India – February 9, 2022 – Stanadyne Managing Director, Near East, Dr. Sanjay Chadda has been honored with a 2021-2022 Indian Achievers’ Award for…

Stanadyne Forms Strategic Distribution Alliance with Diesel Forward

Diesel Forward will be the single central distributor of Stanadyne aftermarket diesel rotary pump products in the North, Central, and South American markets Windsor, Connecticut…