DI LPG Fuel System

The industry’s first medium-duty engine system delivering propane fuel at a constant 350-bar.

system testing

Stanadyne’s liquid propane gas (LPG) direct injectors and fuel pump with Katech-specified flow circuit were installed on a standard 6.6L GDI engine. Katech conducted a 250-hour performance and durability test, successfully demonstrating direct injection propane is viable alternative fuel delivery option for medium-duty (class 3 to 7) engines.

- A robust direct injection fuel system using new hardware and software inhibitor technologies to remove vapor lock barriers specific to propane.

- Stable operation of the engine during hot-start, cold-start, hot-soak, and hot-idle conditions.

- Delivered LPG fuel at high pressure directly into the engine while mitigating the potential for vapor lock.

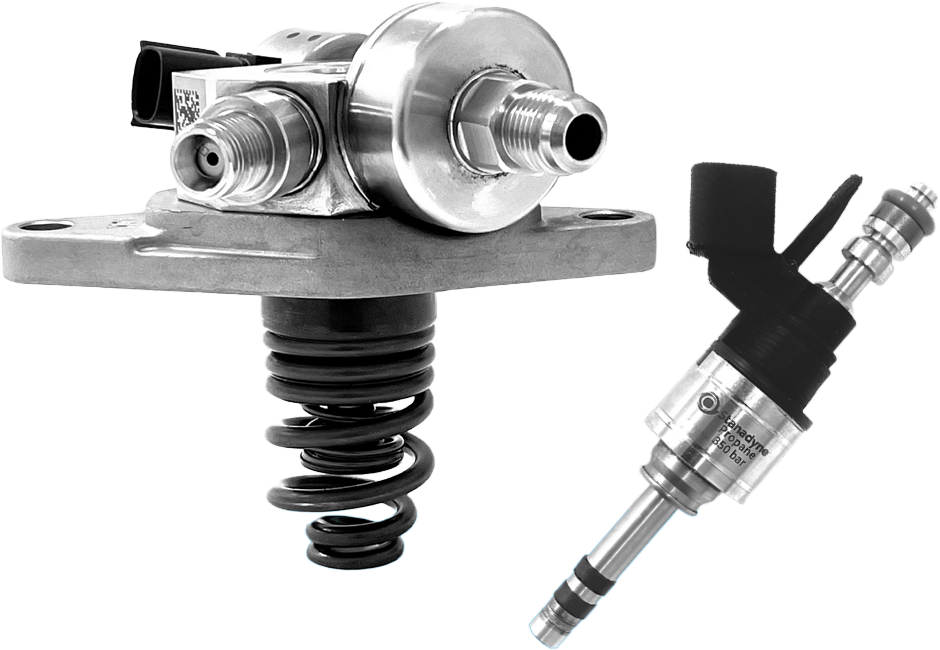

Met All Power & Torque Metrics of the Baseline Gasoline Engine

Using direct injection avoids the 20 percent power reduction associated with port fuel injection.

technical specs

FEATURE |

SPECIFICATION |

|---|---|

| Engine Code | L8T |

| Engine Configuration | V8 |

| Engine Displacement | 6,564 cc |

| Engine Bore | 103.25 mm |

| Engine Stroke | 98 mm |

| Compression Ratio | 10.8:1 |

| Valvetrain Configuration | Pushrod OHV with Variable Valve Timing |

| Valves Per Cylinder | 2 |

| Rated Horsepower GM 2500 | 401 SAE hp @ 5,200 rpm |

| Rated Horsepower Isuzu Class 3-5 | 350 SAE hp @ 4,500 rpm |

| Rated Torque GM 2500 | 464 SAE lb-ft @ 4,000 rpm |

| Rated Torque Isuzu Class 3-5 | 425 SAE lb-ft @ 3,800 rpm |

unique features

Eliminating Vapor Lock

- Katech vapor lock inhibitor hardware and software addresses the design limitations of other LPG direct injection applications.

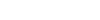

LPG-Specific Fuel Pump

- A modified pump design with a specialized liquid flow path through the pump.

New Injector Design

- An injector with an optimal spray pattern to address the unique properties of liquid propane under high pressure.

- Unique spray hole characteristics and targeting to tightly deliver propane.

- Optimal air-fuel mixing for very efficient combustion that generates the same power output as gasoline.